Engineering And Failure Analysis Services

At METAS, our Engineering Services are designed to provide expert solutions that enhance the durability, efficiency, and performance of your assets. With a focus on long-term sustainability, we specialize in condition assessments, material selection, and engineering consulting to ensure that your projects meet the highest standards of quality and reliability.

Condition Assessment of Concrete Assets

We offer comprehensive condition assessments for concrete assets, providing detailed evaluations that identify and address structural concerns. Our team uses advanced diagnostic techniques to assess the health of your concrete infrastructure, enabling you to make informed decisions about maintenance, repair, and rehabilitation.

Engineering and Materials Selection Consulting

Our engineering and materials selection consulting services ensure that your designs and materials are chosen for their optimal performance and cost-effectiveness. By evaluating your project’s specific needs, we recommend the best materials and engineering approaches to enhance the longevity and reliability of your assets.

PROFESSIONAL SERVICES

Metas also provides a range of specialized professional services to support the integrity of your assets:

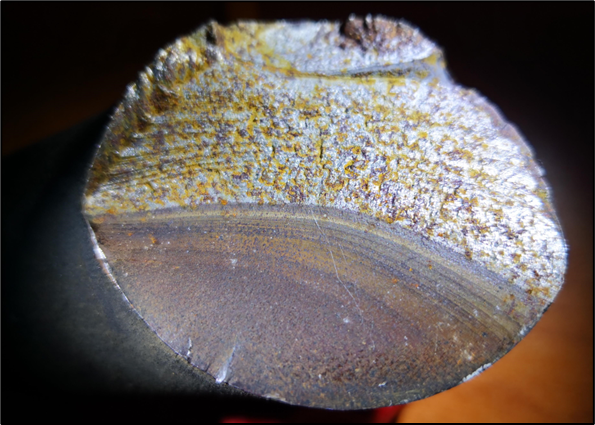

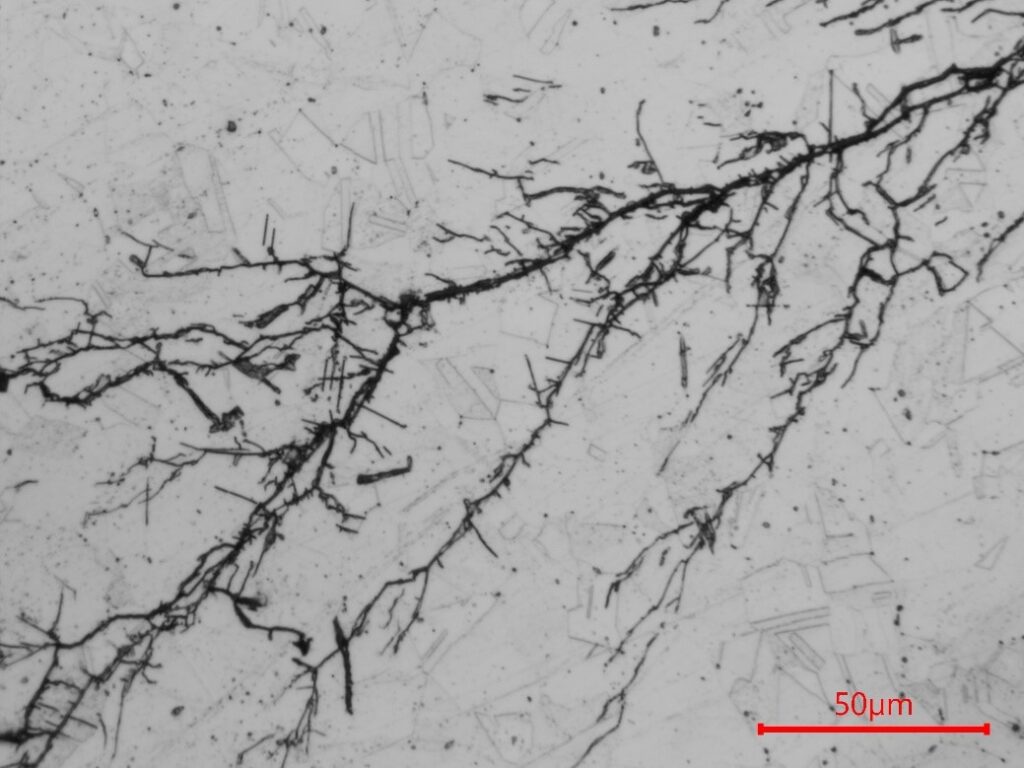

Failure Analysis and Root Cause Analysis

Failure analysis and root cause investigation are critical processes for identifying problems in products, components, or systems. These investigations provide valuable insights into performance issues, enabling the development of effective strategies to prevent future failures.

At METAS, we conduct comprehensive failure investigations to uncover the root causes of issues, offering organizations deeper understanding and actionable solutions. By addressing these challenges, businesses can enhance system reliability, optimize performance, and prevent recurring problems.

Our professional team, consisting of engineers, scientists, and technicians, is very much proficient in identifying and locating the fault in different types of industries e.g., automotive, aerospace, energy, and manufacturing. We use the most advanced state-of-the-art techniques in the investigation for the foundry. Here are some of them: metallurgical assessments, mechanical testing, chemical analysis, and non-destructive evaluation. In the diverse industries of aerospace, automotive, oil & gas, and manufacturing, we offer services that range from examining simple pieces of machinery to carrying out complicated forensic analyses.

The unique and most effective step-by-step approach that METAS employs is the outstanding of all that the competitors can boast about. We start with gathering detail and meticulously processed evidence, then the testing and analysis are designed and implemented by our specifically dedicated and fully technically advanced labs. Along with environmental and in-house testing, we are capable to use microscale data for the integration of different aspects that create clear and irrefutable results. We offer immediate (24/7) on-site support, remote lab assistance, and backing of full-scale testing facilities globally.

The reports we produce are our clients’ assets through which they can get insights into the underlying reasons, contributory factors, and actionable solutions to prevent future failures. These reports are the foundation of strategic decisions, asset integrity, and safety management systems. METAS’s global network also provides experts to testify in complex litigation and insurance claims as well as consultancy to Total Quality Assurance associates. With METAS, companies not only find the solutions to their problems but also get strategic information for reducing the costs and increasing the reliability in the long term.

We’re here to assist you — Contact us Now!

For any inquiries, feel free to reach out to us via email or phone, or schedule a visit to our office.