Material Testing Lab

- Laboratory Services

The METAS team comprises highly qualified metallurgical and mechanical engineers, along with skilled technicians, all equipped with the expertise and education to operate advanced equipment and deliver precise testing data through a wide range of procedures.

METAS specializes in destructive testing, offering comprehensive services in mechanical and physical analysis, metallurgical analysis, and chemical analysis. Whether it involves breaking, polishing, or sparking materials, we have the capability to test virtually any material with accuracy and reliability.

From verifying the reliability of a new product before its launch to conducting detailed failure analyses after an incident, METAS provides integrated testing services designed to deliver accurate and actionable results. Using meticulous microscopic examination, we evaluate critical material properties such as chemical composition, microstructure, tensile strength, and hardness. These insights empower informed decision-making and optimize performance across a variety of applications.

The list of services are not limited but include:

- Material Identification

- Macroscopic Examination

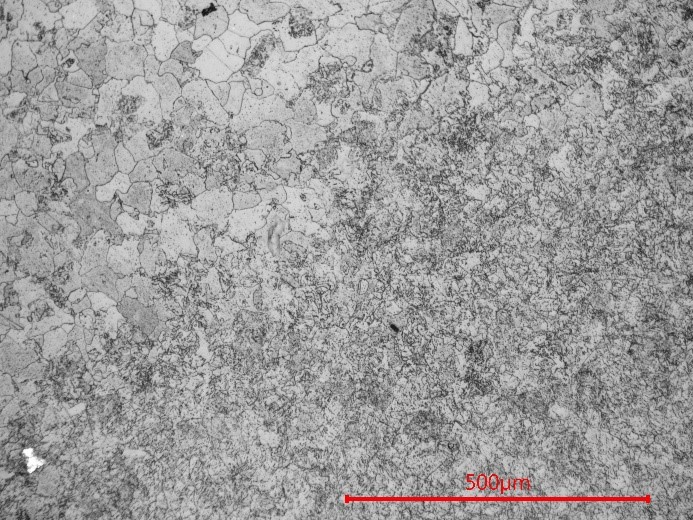

- Metallography and Microstructure analysis

- Micro Constituents Counting

- Case Depth Determination

- Graphite Classification Test

- Microscopic Thickness Measurement

- Grain Size Measurement

- Inclusion Contents Test

- Ferrite Measurement

- Different Hardness

Why Choose METAS For Metallurgical Testing?

At METAS, we are committed to providing reliable, precise, and innovative material testing solutions tailored to meet your specific needs. With a team of experts, advanced equipment, and a focus on industry standards, we ensure unparalleled quality and efficiency in every service we deliver. Here’s what sets us apart:

Broad Capabilities

Our lab is capable of conducting a wide range of tests namely grain size analysis and advanced fractography in order for a clear comprehension of your materials as well as the only source for their life cycle control.

Industry-Specific

Our skilled technicians can conduct accurate discipline-specific testing, for instance decomposing the situation with standard carbon steels to high-performance aerospace grade superalloys (such as Titanium and Aluminum).

Cutting-Edge Developments

With state-of-art equipment and facilities accordingly accredited, we strive to meet the test occasions by innovative material's tailor-made to the fresh phenomena of your development along with our nonpareil experience.

Conservation of Resources:

We use techniques that employ smaller samples and destructive tests only when needed thus saving you a valuable resource.

Material Testing LAB

- Metallographic Replication Services

At METAS, in-situ metallurgical replication, or field metallography, enables the evaluation of the microstructure of samples without the need for cutting them. This approach ensures the uninterrupted operation of equipment while minimizing downtime.

This advanced metallurgical application plays a vital role in industries such as petrochemical, power generation, aerospace, and offshore operations. By providing detailed insights into material conditions, it empowers these sectors to make informed decisions about whether to run, repair, or replace critical components.

What is Metallurgical Replication?

Metallurgical replication involves preparing and etching a metal surface, then using an acetate film to create a detailed negative relief of the microstructure. This replica can be analysed in the field with portable microscopes or in the lab with advanced tools like Scanning Electron Microscopes (SEM), adhering to ASTM standards such as E1351 for precise results.

Key Applications and Benefits

Microstructural Analysis

Creep Damage and Thermal Degradation Assessment

Failure and Crack Analysis

Structural Integrity Verification

The engineers at our company, who have extensive experience working on projects in Australia as well as other countries, utilize the most advanced equipment and adhere to both national and international standards (such as ASTM E3, E340, and E407) to ensure a high degree of precision. Field preparation of materials, including grinding and etching, is tailored individually, and a detailed report with photographic documentation, offering magnifications of up to 1000x, is provided.

Field metallurgical replication offers an efficient and cost-effective solution for Fitness-for-Service (FFS) evaluations in accordance with API 579-1/ASME FFS-1 standards. This method enables the confirmation of critical material properties without the need to halt operations.

At METAS, we enhance replication tests with hardness measurements to provide a comprehensive material assessment. If required, we can also obtain cross-section samples for further analysis. Our safety-trained technicians ensure all processes are conducted safely and efficiently, even in the most challenging environments. We strictly follow established protocols and maintain all necessary Material Safety Data Sheets (MSDS) to deliver reliable results.

We’re here to assist you — Contact us Now!

For any inquiries, feel free to reach out to us via email or phone, or schedule a visit to our office.